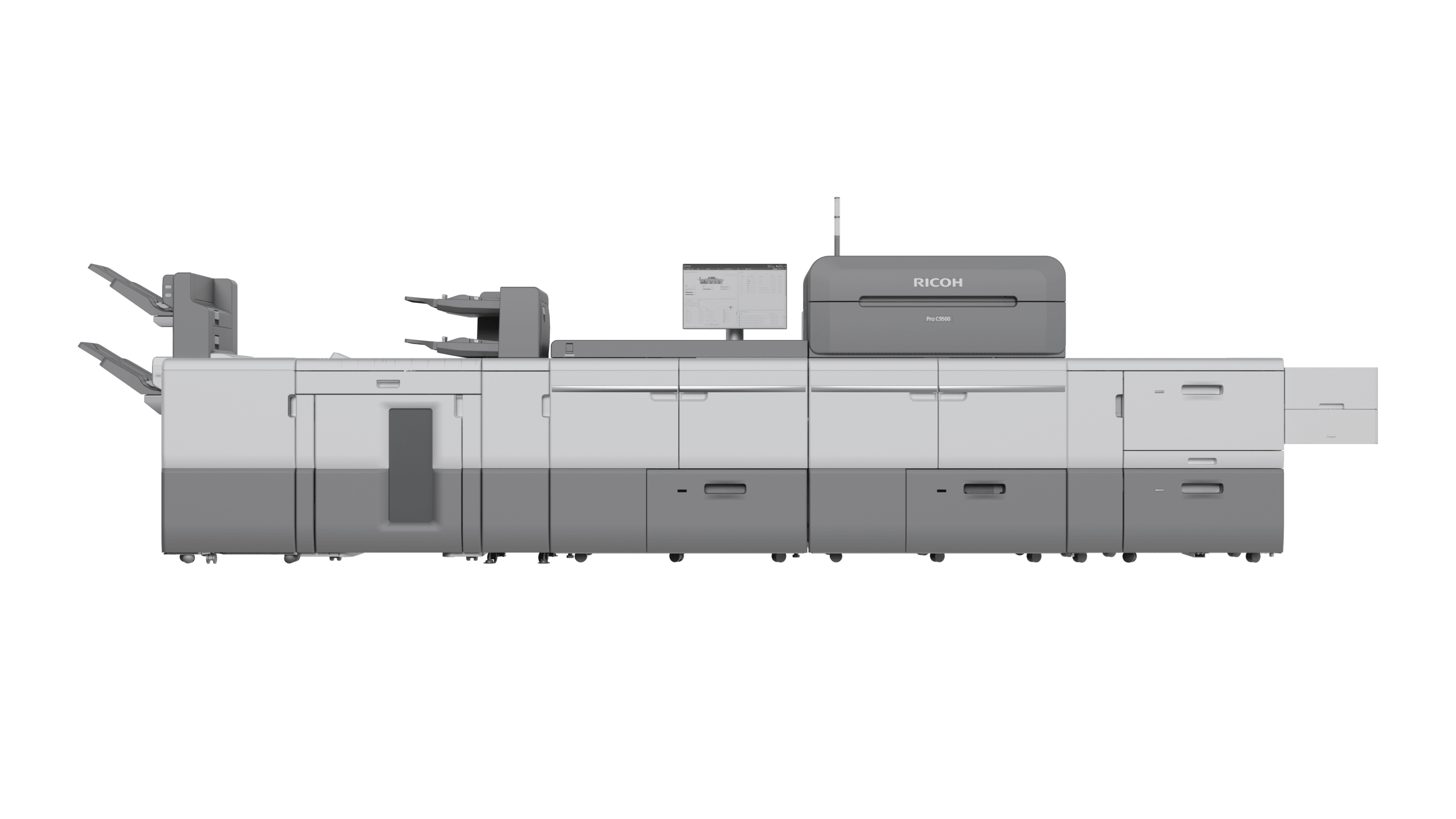

The evolution of the highly popular Ricoh Pro C9200 has been enhanced with performance-improving technologies designed to elevate productivity and quality while simplifying operations and expanding application opportunities. It has improved efficiency and automation while developing greater labour savings throughout the entire workflow. Collectively they support cost control, business expansion, and free up time for other tasks.

The flagship toner-based press has also been developed to enable commercial specialists to further accelerate their analogue to digital transition or confidently upgrade their Print on Demand-oriented digital capabilities.

The newly developed Ricoh GC OS (Graphic Communications Operating System) engine controller has introduced operational and maintenance management improvements. It includes a larger screen with an intuitive and easy-to-use user interface and is compatible with external diagnostic systems and maintenance programmes. Users can access the printer from a PC or tablet, and settings can be remotely managed, saving time, even in a multi-skilled environment where printing operators perform numerous tasks.

Greater automation and operational efficiency are powered by the new Auto Color Diagnosis Unit that automates the three critical inspections in commercial printing: quality, registration, and colour fluctuation. It delivers improved inspection accuracy; while there is now greater efficiency post-inspection with automatic reprinting and purging functions, and the setting procedure is now easier to operate with seven detection levels to choose from.

The Pro C9500 also incorporates proven technologies introduced on the RICOH Pro C9200. They include VCSEL technology (Vertical Cavity Surface Emitting Laser), DEMS (Development Electric-field Modulation System), fusing belt smoothing roller, DSC (Dynamic Shading Correction), registration adjustment, and inline sensor system.